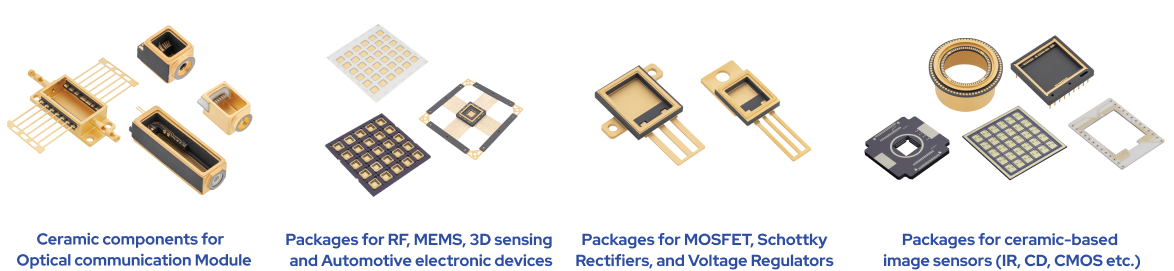

PRODUCTS

PRODUCT

CERAMICS

Ceramic Packages and Substrates

RF Materials provides ceramic packages with superior mechanical properties, suitable for small, high density,

and surface mountable applications. Hermetic or vacuum-sealing is typically applied to ensure device quality.

| Applications | Features |

|---|---|

|

Flexible production capability, accepting small-quantity orders to high volume production requirements |

Optical Communications PKG (TOSA/ROSA, BTF, TO) |

| RF Power TR & High Frequency PKG | |

|

Flexible shape capability by strictly controlled green sheet lamination technology |

Various Sensor Package |

| MEMS, SMD Package | |

|

Range of applications from single-layer to multilayer ceramics (Mo/Mn , W etc.) |

Hybrid IC with mixed Power circuit |

| Ceramic Heater | |

|

RFMTL assists in design optimization by providing electrical and thermal simulations |

- |

| - |

HTCC Multilayer Ceramics Technologies

We are building a ceramic manufacturing platform with a laminate structure based on HTCC. Due to its multilayered

structure, circuit designs can be delivered flexibly through layers and complex structures, e.g. cavity structures, are available.

Green Sheet Tape Casting & Sheet Forming

-

Ceramic green sheets are manufactured by the doctor blade method

under strict control - Manufactured thickness range is 0.02~0.5mm (6~12"/sq)

Processing Via and Cavities

-

Processing holes and cavities on ceramic sheets using a punching

pin-die unit -

Drilling & scribing work process on green sheet using CO₂

and IR laser source

Screen Printing and Lamination

- Printing process for multilayer boards and via-hole filling

- Green sheet lamination process of Multi-layer boards

High Temperature Co-Firing

-

Ceramic firing conditions are produced by Co-debinding & Co-firing in a

humidified hydrogen atmosphere

Ceramic Material Properties and Design Rules

Various bar stacks can meet the needs of diverse customers. We manufacture package and do

packaging in house

Material Properties

| Item | Unit | HTCC | |

|---|---|---|---|

| White | Black | ||

| Material name | - | MHA-94 | MBA-92 |

| Dielectric Constant |

@ 1MHz 10GHz |

9.4 8.8 |

9.8 9.2 |

| Dielectric loss tangent (Tan δ) | @ 1MHz 10GHz |

5x10⁻⁴ 1x10⁻³ |

4x10⁻⁴ 1x10⁻³ |

| Thermal conductivity | W/mK | 26 | 17 |

| TCE | ppm/°C | 7.5 | 7.4 |

| Density | g/cm² | 3.6 | 3.6 |

| Flexural strength | MPa | >350 | >350 |

| Conductor Materials | - | W, Mc | W, Mo |

| Volume Resistivity | Ω.cm | >1012 | >1012 |

| Alumina contents | % | 94 | 92 |

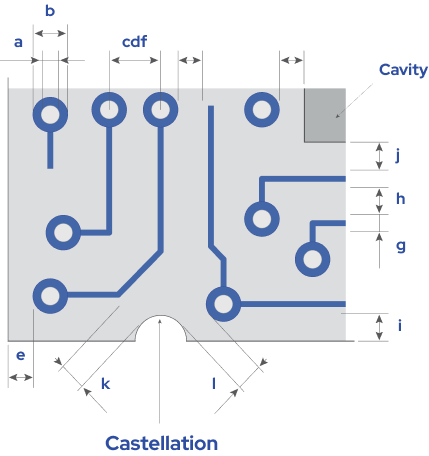

Design Rules for HTCC (EXPOSED SURFACE LAYER)

| Location | Spec. | |

|---|---|---|

| a | Via Hole Diameter | ≥150 |

| b | Via Hole Land | ≥400 |

| c | Via Hole Pitch | ≥650 |

| d |

Via Catch Pad to Line

- w/Via from Upper layer - w/o Via from Upper layer |

≥300 ≥200 |

| e | Via Catch Pad to Substrate Edge | ≥650 |

| f | Via Catch Pad to Cavity Edge | ≥650 |

| g | Line Width | ≥150 |

| h | Line Spacing | ≥100 |

| i | Line to Substrate Edge | ≥500 |

| j | Line to Cavity Edge | ≥500 |

| k | Castellation to Line | ≥250 |

| l | Castellation to Via Catch Pad | ≥300 |